India’s lace industry has woven an intricate tapestry of beauty and craftsmanship for centuries. With its renowned artisans and innovative designs, India emerges as a global leader in lace manufacturing. Let’s delve into the vibrant world of lace manufacturers in India, exploring their skills, products, and the myriad ways to incorporate this delicate fabric into your life.

Unlocking the Treasures of Indian Lace

India’s lace industry boasts a rich history dating back to the Mughal era. The country’s skilled artisans have mastered the art of creating exquisite lace designs using traditional techniques that have been passed down through generations. Today, India’s lace manufacturers export their products to over 100 countries worldwide, making a significant contribution to the industry’s global market share.

The Enchanting Allure of Lace

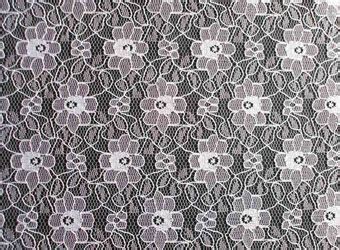

Lace has captivated hearts for centuries with its intricate patterns and delicate beauty. It adds a touch of elegance and sophistication to any outfit or décor. Lace’s versatile nature allows it to be used in a wide range of applications, from fashion and accessories to home textiles and interior design.

Exploring the Diverse Range of Lace Products

India’s lace manufacturers offer a captivating array of products to cater to the diverse tastes and needs of customers.

1. Embroidered Lace

Embroidered lace features intricate patterns created by embroidering threads onto a base fabric. This technique allows for countless design possibilities, from floral motifs to geometric shapes.

2. Guipure Lace

Guipure lace is a delicate and openwork fabric made from fine cotton or silk threads. Its distinctive feature is its raised or embossed patterns, creating a lace with a three-dimensional effect.

3. Chemical Lace

Chemical lace is produced using a chemical process that dissolves parts of the base fabric, leaving behind a delicate and intricate pattern. This technique allows for highly detailed and precise designs.

4. Raschel Lace

Raschel lace is made on a special type of knitting machine. It is characterized by its soft and stretchy nature, making it ideal for garments and lingerie.

Uncovering the Needs and Wants of Customers

Lace manufacturers in India are attuned to the ever-evolving needs and desires of their customers. They continuously innovate and explore new designs to meet the demands of the global market.

Meeting Customer Demands

To ensure customer satisfaction, lace manufacturers prioritize:

- Quality: Adhering to strict quality standards to deliver flawless products

- Customization: Offering personalized lace solutions tailored to specific requirements

- Timely Delivery: Meeting deadlines and ensuring prompt delivery

Avoiding Common Mistakes in Lace Manufacturing

Navigating the world of lace manufacturing can present potential pitfalls. Here are some common mistakes to avoid:

- Compromising Quality: Sacrificing quality in favor of lower costs can lead to customer dissatisfaction and reputational damage.

- Ignoring Market Trends: Failing to stay abreast of emerging lace trends can limit market potential and hinder growth.

- Inefficient Production Processes: Inadequate production processes can lead to delays, waste, and reduced profitability.

Advantages and Disadvantages of Lace Manufacturing in India

Advantages:

- Skilled Artisanship: India’s lace manufacturers possess exceptional craftsmanship and technical expertise.

- Competitive Pricing: India offers competitive production costs, making its lace products accessible to a wide range of customers.

- Wide Variety of Designs: The industry offers a vast selection of lace designs, catering to diverse preferences and applications.

Disadvantages:

- Labor Costs: While India’s labor costs are generally lower than other lace-producing countries, they can still impact production costs.

- Power and Infrastructure: Intermittent power supply and infrastructure limitations can sometimes pose challenges to manufacturers.

- Environmental Concerns: The lace manufacturing process can involve the use of chemicals, which must be managed responsibly to minimize environmental impact.

Inspiring Innovation: The Future of Indian Lace

As the lace industry continues to evolve, India’s manufacturers are embracing new technologies and design concepts to drive innovation.

Embracing Digitalization: Digital design tools and 3D modeling are transforming the lace creation process, allowing for greater precision and customization.

Exploring Sustainable Materials: Lace manufacturers are exploring sustainable materials such as organic cotton and recycled fibers to meet the growing demand for eco-conscious products.

Cradle-to-Cradle Approach: The industry is adopting cradle-to-cradle principles, aiming to design and produce lace that is recyclable and environmentally friendly.

Table 1: Global Lace Market Size and Projections

| Year | Market Size (USD Billion) | Projected Growth |

|---|---|---|

| 2021 | 120.8 | 5.6% CAGR |

| 2030 | 203.5 |

Source: Grand View Research

Table 2: India’s Lace Exports

| Destination | Share |

|---|---|

| United States | 28.5% |

| United Kingdom | 12.3% |

| Germany | 10.6% |

| France | 7.5% |

| Italy | 6.4% |

Source: Trade Map

Table 3: Factors Driving the Demand for Lace

| Factor | Explanation |

|---|---|

| Growing Fashion Industry | Lace is widely used in apparel and accessories, driving demand. |

| Interior Design Trends | Lace is gaining popularity for home décor applications. |

| Customization Options | Lace’s versatility allows for personalized designs, meeting customer preferences. |

| Sustainable Lace | Consumers are increasingly seeking eco-conscious lace products. |

Table 4: Challenges Faced by Lace Manufacturers in India

| Challenge | Description |

|---|---|

| Labor Availability | The industry faces challenges in securing skilled labor. |

| Infrastructure Gaps | Limited access to reliable power and infrastructure can hinder production. |

| Trade Barriers | Import tariffs and quotas can affect the competitiveness of Indian lace in certain markets. |

Conclusion

Lace manufacturers in India stand as a testament to the country’s rich heritage of craftsmanship and design. With their unparalleled skills, innovative spirit, and unwavering commitment to quality, they continue to captivate the world with their exquisite lace creations. As the industry embraces sustainable practices and explores new frontiers in design, India’s lace manufacturers are poised to further expand their global footprint and redefine the boundaries of this delicate and enduring fabric.